1. Frosting Process

The frosting process is a process in which the originally smooth surface object becomes not smooth and the light shines on the surface to form a diffuse reflection. In the chemical frosting treatment, the glass is mechanically ground or manually ground with abrasive materials such as emery, silica sand, and pomegranate powder to make a uniformly rough surface, and the surface of the glass and other objects can also be processed with the hydrofluoric acid solution, and the resulting product becomes frosted glass.

2. Sandblasting Process

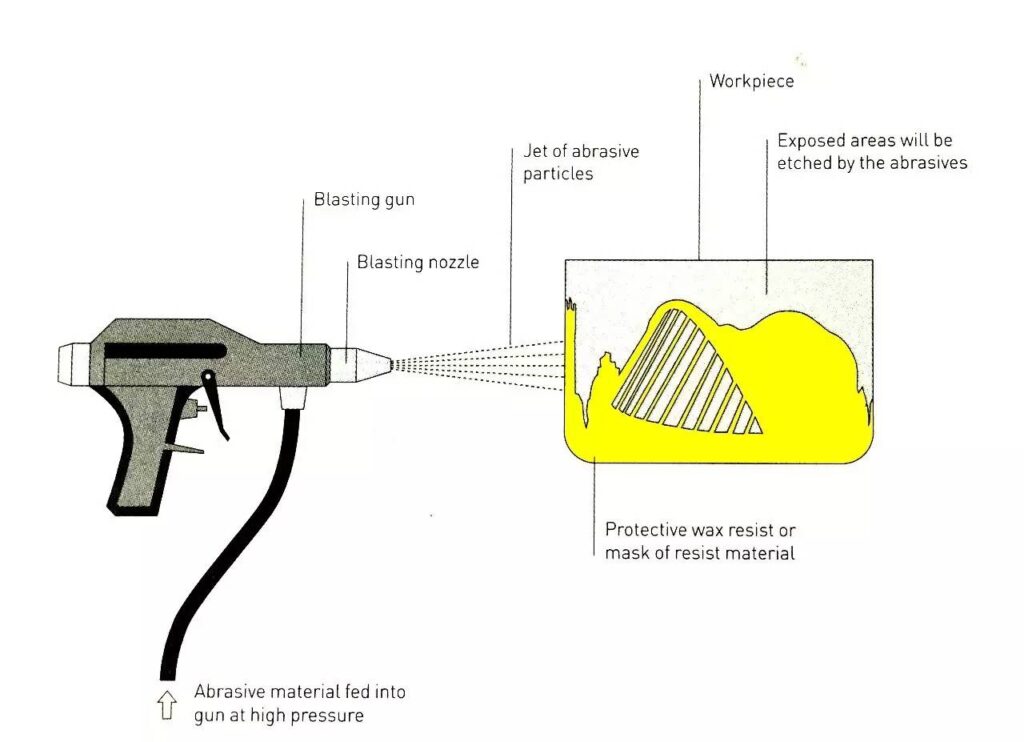

Sandblasting is a kind of compressed air the power to promote abrasive to the workpiece surface for the treatment of work called sandblasting, that is, we often say shot cleaning, shot peening enhanced treatment. Because in the early days of shot blasting technology, and was the only abrasive that could be used, so at that time and for quite a long time afterward, shot blasting was always called sandblasting.

Sandblasting can make the surface be cleaned at the same time to obtain the required cleanliness and make the surface get a certain roughness, improving the adhesion of the coating on the basic surface of two effects. No matter how good the paint is, it can not be attached to the surface of the workpiece without surface treatment for a long time.

The role of surface pretreatment is to clean the surface and create the required roughness on the surface to “lock in” the coating. After the surface of the sandblasted workpiece is coated with a good-performance of industrial paint, the coating life can be more than 3.5 times higher than the same quality coating on the surface treated by other methods. Another advantage of sandblasting (shot blasting) is that the surface roughness can be determined in advance according to the requirements and is easily achieved during the cleaning process.

3. The difference between GLASS frosting and sandblasting

(1) Frosting process

The frosting process refers to the glass immersed in a prepared acidic liquid (or the application of acidic paste) using strong acid to erode the surface of the glass, while the ammonia hydrogen fluoride in the strong acid solution causes the glass surface to form crystals. Therefore, if the frosting process is done well, the surface of the frosted glass is unusually smooth, and the hazy effect is generated by the scattering of crystals. If the surface is rough, it means that the acid erosion of the glass is more serious, which belongs to the immature performance of the scrub master. Or some parts are still not crystallized (commonly known as not ground to sand, or the glass has spots) and also belong to the master’s poor process control. Technology is difficult. The process is characterized by the appearance of sparkling crystals on the glass surface, which is formed under critical conditions, mainly because the ammonia hydrogen fluoride has reached a time of fast consumption. In order to achieve this state, many manufacturers have conducted many attempts to study, but have been unable to break through this difficulty.

(2) Sandblasting process

The process is very common, it is the use of a spray gun high-speed shot sand hit the glass surface, so that the glass formed a fine concave and convex surface, so as to achieve the effect of scattering light so that the light through the formation of a hazy feeling. The surface of the glass product of the sandblasting process feels rough, and because the glass surface is damaged, it seems that the glass of the original bright material seems to be white glass. The process is of average difficulty.

The two processes are completely different processes, frosted glass is higher than sandblasted glass in terms of cost, and the effect mainly depends on the needs of users. Some unique glasses don’t work well with frosting either. From the pursuit of a noble point of view, one should choose frosted. The sandblasting process can be completed by the general factory, and the sanding process is not easy to really do well.