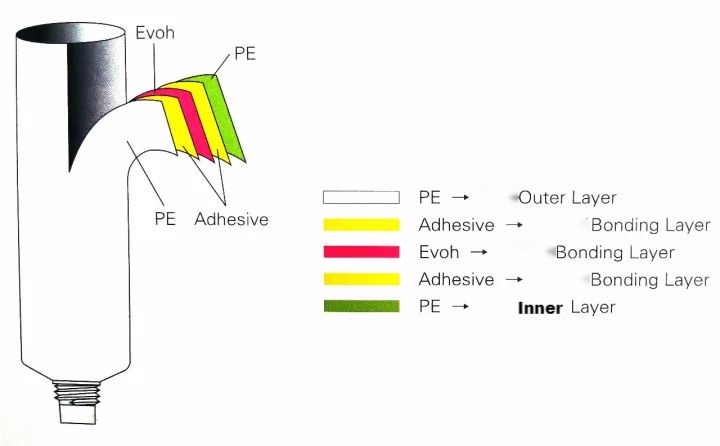

From the above picture, we can find that there are five layers. The outer layer, bonding layer, isolation layer, bonding layer, and inner layer for a five-layer tube.

If the contents of the packaging of the daily chemical company are some products that are particularly sensitive to oxygen (such as some whitening cosmetics) or whose fragrance is very volatile (such as essential oils or some oils, acids, salts, and other corrosive chemicals), five layers of co-extruded tubes should be selected at this time. Because the oxygen transmission rate of the five-layer coextruded tube (polyethylene/binder resin/EVOH/binder resin/polyethylene) is 0.2-1.2 units, and the oxygen transmission rate of the ordinary polyethylene two-layer tube is 150-300 units. In a certain period, the weight loss rate of a coextruded tube containing ethanol is several times lower than that of a two-layer tube. In addition, EVOH is an ethylene-vinyl alcohol copolymer with excellent barrier properties and fragrance preservation (a thickness of 15-20 microns is the best effect).

The five-layer tube is characterized by good gas barrier performance, which can effectively prevent the infiltration of oxygen and odor and the seepage of special flavors and active ingredients. Usually, foundation, sunscreen, and isolation cream will choose five layers of tubes, and the difference between two-layer tubes is that there is an adhesive film in the middle.

EPOCH Packaging provides all kinds of cosmetic tubes, let’s talk more!