The water transfer printing process, is a beautification process on the surface of the product, because the transfer effect is natural, and can adapt to the mainstream packaging material cladding, water transfer printing product effect, can imitate marble, bamboo, wood, etc., which colleagues in the cosmetics industry deeply like, this article we share basic knowledge of water transfer printing process and its process quality inspection project description, for the reference of friends: Water transfer printing process, as a beautification process on the surface of the product, because the transfer effect is natural, and can adapt to the mainstream packaging material cladding, the product effect of water transfer printing can imitate marble, bamboo, and wood, etc., which colleagues in the cosmetics industry like this article we share basic knowledge of water transfer process and its process quality inspection project description for reference:

- Water transfer printing process flow

Making water transfer printing paper → paper soaking → pattern transfer → drying → finished product

- The production of water transfer printing paper: After computer processing according to the required pattern, output the negative plate, then print the colorful design on the water transfer paper (the specially treated paper does not need to be processed), and print the cover oil on the printed pattern paper. Another method is to use a color laser printer to print the pattern directly to the water transfer paper and then water transfer.

- Flower paper soaking: Put the printed floral form in water, soak for 30 seconds, and then remove it from the water, so that it can slide. Be careful not to soak for too long, otherwise, it will dissolve the glue on the paper’s surface.

- Pattern transfer: First of all, the surface of the object to be transferred is treated, and then the soaked flower paper is transferred to it, and then the excess water is scraped and dried.

- Dry: Metal, ceramic, glass, and other items in the oven, at 140℃ for 20 minutes; Plastic items are roasted at 70℃ for 60 minutes; Candles, helmets, or reinforced glass are not baked.

- Finished product: Spray a layer of transparent finish paint on the surface of the baked goods, and dry for 12h, so that the flower surface and the decoration are permanently combined. If you do not do this process can also, but the fastness is not good.

2. Water transfer printing process operation

- Coating film: The water-soluble film is pre-printed with the desired pattern;

- Activating: A special solvent is used to activate the pattern on the film into an ink state.

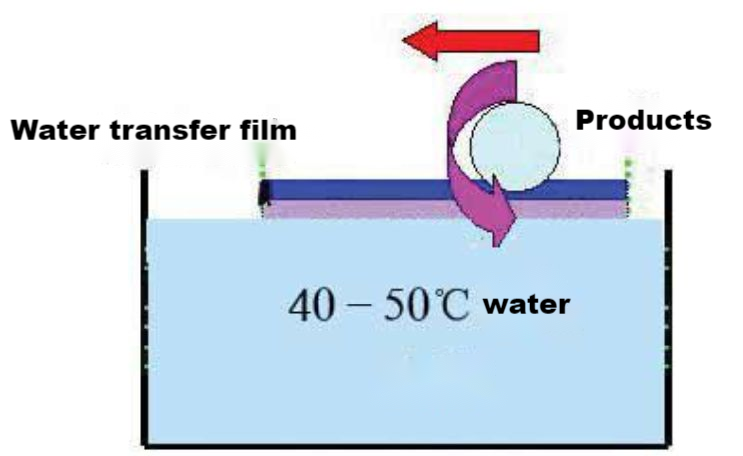

- Cubic Transfer: The pattern is transferred to the printed object using water pressure.

- Water Scrubbing: Rinse the impurities remaining on the printed workpiece with water.

- Dry: Dry the printed workpiece.

- Surface Spray Paint: Spray PU transparent gloss to protect the surface of the printed workpiece.

- Redrying: Dry the surface of the coated object.

3. There are two types of water transfer printing technology

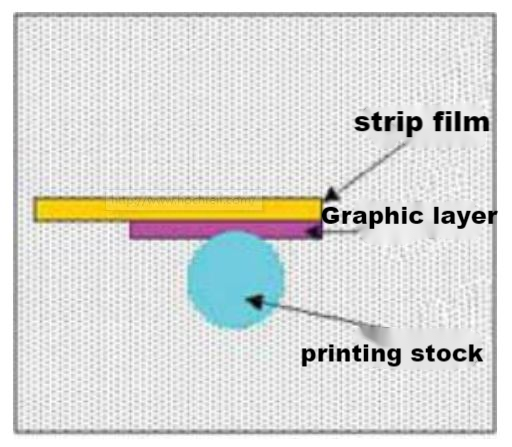

One is the water label transfer technology, and the other is the water coating transfer technology, the former mainly completes the transfer of text and photo patterns, and the latter tends to complete the transfer on the entire product surface. CubicTransfer technology uses a water-based film that is easily dissolved in water to hold images. Due to the excellent tension of the water-coated film, it is easy to wrap around the surface of the product to form a graphic layer, and the surface of the product is like spray paint to get a completely different appearance. Coating transfer technology can cover the color pattern on any shape of the workpiece, for manufacturers to solve the problem of three-dimensional product printing. The curved coating can also add different patterns to the surface of the product, such as leather, wood, jade, and marble, etc., and also avoid the common spot in the color of the general board printing. In the printing process, because the product surface does not need to be in contact with the printing film, damage to the product surface and its integrity can be avoided.

Water transfer printing film with special chemical treatment, after printing the required color lines, flat sent to the surface of the water, the use of water pressure, the color pattern evenly transferred to the surface of the product, at this time the coated film is automatically dissolved in water, after cleaning and drying, and then a layer of transparent protective coating, then the product has shown a completely different visual effect.

4. Water transfer printing inspection items

- Grade plane division standard

A side: the outer surface often seen after assembly, the top surface, and the side view surface that ordinary people can see without bending over.

B side: A plane that is not often seen, but can be seen under certain conditions. Such as side, bottom, etc.

- Test Condition

A Light source requirement: Arctic daylight or indoor high-efficiency fluorescent lamp with two light sources (lighting degree of about 1000 lumens).

B Visual distance: Class A surface is 300mm, and Class B surface is 500mm.

Inspection standards according to the requirements of the light source standard to distinguish the grade surface of the product, all grades of the surface coating film should be free of substrate exposure, peeling, and other defects and all surfaces should be free of scratches, bubbles, wrinkles, pinholes, accumulation of powder and other undesirable phenomena. At the standard point of the eye distance grade plane, scan at a speed of 3cm/s.

5. Performance criterion

- Non-destructive test item luster: The gloss meter is used to determine that the incidence Angle is 60° and the error test of ±5% is qualified. Color: The color must conform to the design drawing and color plate comparison without obvious differences.

- Test for adhesive force: Baig test method: After spraying, take a color plate, on the coating surface, at an interval of 1mm, horizontal and horizontal parallel to carve 11 lines, with appropriate strength (scratches to expose the matrix) on the spray surface into 100 squares, and then cover with 3M tape and press tightly, at a 45° Angle, and then pull at a speed of 100mm/min, at this time check whether the objects in the square fall. The acceptance standard is 0~1, that is, the shedding area is not more than 5%.

- Hardness test: Use a sharpened HB pencil, fixed in the middle of the horizontal trolley, at a 45° Angle with the coating surface, push forward in a straight line for 15~30mm, and check the coating surface after wiping the scratch with an eraser. Criteria: no scratches show six dew is qualified.

- Solvent resistance test: Wet a cotton stick with analytical alcohol (99.8% anhydrous alcohol), and wipe the coating surface 50 times with a force of 1 kg, the eligibility standard is: the outer film shall not have any peeling, discoloring, or rising phenomenon, which can allow a little change in gloss.

- Impulse withstand test: The use of test equipment, with 500 grams of weight hammer from a height of 500mm free fall, the criterion is 1/4 of the punch positive impact, the surface coating film without cracking, falling film phenomenon.